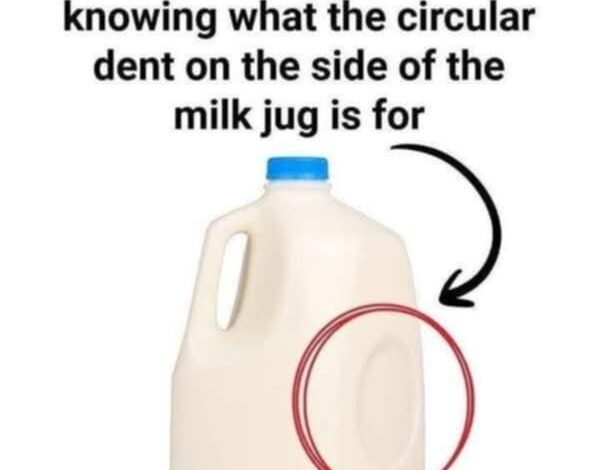

The Hidden Function of Circular Indentations on Milk Containers: What Consumers Need to Know

Have you ever wondered about the mysterious circular indentation on the side of your plastic milk container? This seemingly minor design feature serves a crucial purpose in food packaging technology that impacts product quality, storage efficiency, and consumer satisfaction.

The Mystery Behind Milk Container Design Revealed

Many consumers remain unaware of this subtle but ingenious packaging element. As one viral social media post—which garnered hundreds of comments—observed, “Most people will complete their lives without discovering the true purpose of the circular indentation on milk containers.”

Common Misconceptions About Milk Container Indentations

Several theories circulate online regarding these indentations. Social media user Cory Anderson suggested, “When the indentation bulges outward, it indicates the milk is spoiling.”

Another popular theory connects the feature to temperature adaptation. Facebook user Andrew Serpico explained, “The indentation provides expansion space for the milk, preventing container rupture if frozen.”

The Scientific Purpose Revealed by Dairy Experts

According to authoritative information from The Dairy Alliance, a reputable organization specializing in dairy education and advocacy, these indentations—technically called “panels”—serve multiple functional purposes beyond aesthetic design:

- They provide essential structural stability to hold liquid contents securely

- They help regulate precise volume measurement during the filling process

- They accommodate temperature-related expansion and contraction

The Dairy Alliance explicitly clarifies that these indentations have no relation to spoilage detection: “The panel wouldn’t bulge due to milk aging, although such a spoilage indicator would certainly benefit consumers navigating confusing food expiration labeling.”

Temperature Adaptation and Quality Control

Food Republic, a trusted source for culinary information, explains that these panels are deliberately engineered slightly larger in warmer conditions because plastic contracts during summer heat. Conversely, indentations appear smaller during colder months. This intelligent design ensures consumers receive consistent volume regardless of seasonal temperature variations.

Engineering Insights from Packaging Technology Experts

A comprehensive technical analysis by product development specialists Lauren Joshi and John Cowan (published June 2017) reveals that container shrinkage is an unavoidable characteristic in dairy packaging because high-density polyethylene (HDPE) containers naturally contract post-manufacturing.

These strategically designed indentations help manufacturers:

- Prevent costly product overflow incidents

- Maintain visually appealing, fuller-looking containers

- Optimize production efficiency without compromising product quality

This engineering solution addresses key factors in consumer satisfaction while controlling manufacturing costs in the competitive dairy products marketplace.